|

ELECTRICS

CRUCIBLES FURNACES |

|

|

BALE-OUT |

|

T max 1100°C,

1200°C and 1300°C

Rugged casing construction.

Compact construction, easy access to metal bath.

Excellent thermal insulation.

Low energy consumption, low operating costs (approx. 0,4 KWh/ kg

aluminium).

High - quality heating elements wound on ceramic

tubes.

Uniform heating of melt and crucible due to heating

from 4 sides, superb metal quality, good crucible

life.

Heat resistant cast-iron ring on removable concrete

cover protects crucible against mechanical damage

and allows easy access for crucible change.

Emergency outlet drain.

Cable harness between control panel and furnace

protected by flexible metal

conduit, providing optimum protection against

mechanical damage.

Low maintenance costs. |

|

|

TECHNICAL DATA |

|

|

Model |

Crucible |

Melting rate

(kg/h Al at 700 °C) |

Melting rate

(kg Cu at 1000 °C) |

Power

(kw) |

T max

(°C) |

Outside

Dimensions

(mm) |

Voltage

(V) |

Weight

(kg) |

|

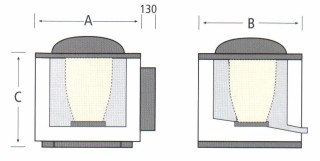

A |

B |

C |

|

TA 30/11 |

A 70 |

35 |

- |

18 |

1100 |

860 |

860 |

810 |

400 3/N |

500 |

|

TA 50/11 |

A 150 |

45 |

- |

21 |

1100 |

860 |

860 |

870 |

400 3/N |

570 |

|

TA 100/11 |

A 300 |

60 |

- |

27 |

1100 |

1010 |

1010 |

910 |

400 3/N |

710 |

|

TA 200/11 |

BU 200 |

130 |

- |

53 |

1100 |

1160 |

1160 |

950 |

400 3/N |

810 |

|

TA 300/11 |

BU 300 |

140 |

- |

63 |

1100 |

1210 |

1210 |

1050 |

400 3/N |

1070 |

|

TA 350/11 |

BU 350 |

160 |

- |

68 |

1100 |

1210 |

1210 |

1270 |

400 3/N |

1120 |

|

TA 500/11 |

BU 500 |

170 |

- |

72 |

1100 |

1390 |

1390 |

1270 |

400 3/N |

1300 |

|

TA 600/11 |

BU 600 |

210 |

- |

82 |

1100 |

1390 |

1390 |

1420 |

400 3/N |

1420 |

|

TA 800/11 |

BU 800 |

260 |

- |

102 |

1100 |

1430 |

1430 |

1490 |

400 3/N |

2300 |

| |

|

|

|

|

|

|

|

|

|

|

|

TK 70/12 |

A 70 |

35 |

50 |

18 |

1200 |

860 |

860 |

810 |

400 3/N |

720 |

|

TK 150/12 |

A 150 |

45 |

65 |

21 |

1200 |

860 |

860 |

870 |

400 3/N |

790 |

|

TK 300/12 |

A 300 |

60 |

85 |

27 |

1200 |

1010 |

1010 |

910 |

400 3/N |

920 |

|

TK 500/12 |

BU 200 |

130 |

195 |

53 |

1200 |

1160 |

1160 |

950 |

400 3/N |

1150 |

| |

|

|

|

|

|

|

|

|

|

|

|

TK 70/13 |

A 70 |

35 |

50 |

18 |

1300 |

860 |

860 |

810 |

400 3/N |

720 |

|

TK 150/13 |

A 150 |

45 |

65 |

21 |

1300 |

860 |

860 |

870 |

400 3/N |

790 |

|

TK 300/13 |

A 300 |

60 |

85 |

27 |

1300 |

1010 |

1010 |

910 |

400 3/N |

920 |

|

TK 500/13 |

BU 200 |

130 |

195 |

53 |

1300 |

1160 |

1160 |

950 |

400 3/N |

1150 |

|

|

|

|

ELECTRIC

CRUCIBLES FURNACES

|

|

MELTING |

|

T max 1200 °C

and 1300 °C

Rugged casing construction.

Safe, reliable pouring using 2 hydraulic cylinders

with end bearing dampers on tilting frame.

Precision dosing at every tilting angle.

Excellent thermal insulation.

Low energy consumption, low operating costs (approx. 0,4 KWh/ kg

aluminium).

High - quality heating elements wound on ceramic

tubes.

Uniform heating of melt and crucible due to heating

from 3 sides, superb metal quality, good crucible

life.

Crucible protected by cover plate made of refractoty

concrete.

Emergency outlet drain.

Cable harness between control panel and furnace

protected by flexible metal

conduit, providing optimum protection against

mechanical damage.

Low maintenance costs.

|

|

|

|

TECHNICAL

DATA |

|

|

|

Model |

Crucible |

Melting rate

(kg/h Al at 700 °C) |

Melting rate

(kg Cu at 1000 °C) |

Power

(kw) |

T max

(°C) |

OutsideDimensions

(mm) |

Voltage

(V) |

Weight

(kg) |

|

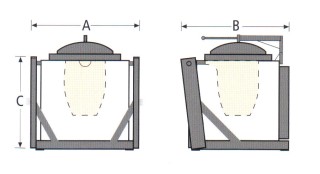

A |

B |

C |

|

TA 30/12/K |

A 70 |

32 |

47 |

18 |

1200 |

1540 |

1300 |

1160 |

400 3/N |

950 |

|

TA 50/12/K |

A 150 |

42 |

62 |

21 |

1200 |

1600 |

1400 |

1250 |

400 3/N |

1200 |

|

TA100/12/K |

A 300 |

57 |

82 |

27 |

1200 |

1850 |

1550 |

1270 |

400 3/N |

1600 |

|

TA200/12/K |

TP 287 |

125 |

190 |

53 |

1200 |

1950 |

1600 |

1400 |

400 3/N |

1790 |

|

TA350/12/K |

TP 412 |

150 |

- |

63 |

1200 |

2000 |

1650 |

1460 |

400 3/N |

2180 |

|

TA600/12/K |

TP 587 |

205 |

- |

82 |

1200 |

2150 |

1900 |

1670 |

400 3/N |

2820 |

|

TA800/12/K |

TBN 800 |

255 |

- |

102 |

1200 |

2250 |

2000 |

1670 |

400 3/N |

3500 |

| |

|

|

|

|

|

|

|

|

|

|

|

TK 70/13/K |

A 70 |

32 |

47 |

18 |

1300 |

1540 |

1300 |

1160 |

400 3/N |

980 |

|

TK150/13/K |

A 150 |

42 |

62 |

21 |

1300 |

1600 |

1400 |

1250 |

400 3/N |

1300 |

|

TK300/13/K |

A 300 |

57 |

82 |

27 |

1300 |

1850 |

1550 |

1270 |

400 3/N |

1650 |

|

TK500/13/K |

TP 287 |

125 |

190 |

53 |

1300 |

1950 |

1600 |

1400 |

400 3/N |

1850 |

|

|

|